The use of Dielectric Grease to protect Coaxial Connectors from moisture and corrosion by filling has produced false information about it's effect on connector properties and thus much confusion in the Communications Installers group.

Filling of a coaxial connector with dielectric grease will not hamper electrical throughput but will alter its passage of electromagnetic energy ( RF).

Depending on connector impedance matching properties of the connector, RF frequency , interior void size and density of the filler used: Significant reflection losses may occur.

See links to " More on Dielectrics " and " Stuf Formulation " on this page.

Choosing a low density ( dielectric constant ) filler which closest approached the dielectric properties of air is best suited.

STUF Dielectric Waterproofing Filler approaches the dielectric equivalent of air as close as possible and will least alter the connector impedence and signal throughput of all know dielectric greases produced today.

STUF is the only dielectric weather protecting filler for coaxial connectors specifically formulated for this purpose available.

Protecting Coaxial Connectors from Moisture and Weather with STUF Dielectric Grease Filler

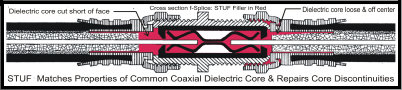

STUF is a filler, specifically formulated for use in connectors used on coaxial cables. It is formulated to simulate the dielectric properties of foam polyethelene (common coaxial cable core). For more on how STUF is formulated go :________And more information on Dielectrics : _______

Directions: Mate tube of STUF to connector cap end and fill.

Thread connector and snug with wrench, A resistance to

tightening should be noted as STUF is channeled into voids

*Ultimate signal throughput performance will be realized

after STUF fluids migrate, (one week), forming a moisture

impermeable, clay like , Teflon - Silica compound.

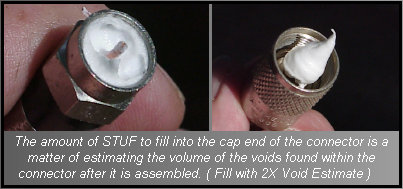

Filling volume is a "pea" sized for smaller f-connector sizes

and 2 - 3 "peas" for larger connectors: PL,UHF,N, BNC,TNC

type connectors. The STUF volume applied should be twice

the estimated void volume after the connector is assembled.

Depositing a good fill amount of STUF is most easily done upon the center conductor of the " Cap " side of the connector assembly. When assembled and tightened; STUF is compressed, channeled into internal voids, reducing it's volume as the glass microspheres and teflon particles pack and the oils extrude into threads, machined borders and the cable braid area.

Opening up the connector for inspection should show STUF deposited in the interior

of the connector in a circular symetrical fashion ( see pic at right ). Inspection should be

done any time a new type of connector is used to verify proper fill volume & full Seating.

To Reassemble : Deposit +/- 1/2 pea of STUF again on the center conductor to make

up for any STUF filler "lost" during assembly opening, Reassemble and re-tighten.

STUF is a viscious dielectric and will not interfere with electrical contacts within the

connector or continuity of electrictricity through the connection. ( Like Air )

A Note on N - Style ( Rubber back sealed ) Connectors: ( Photo at right )

Some connectors use a rear seal within the connector. This seal can stop the

extrusion of STUF into the rear area of the connector and through the parts borders.

In these types of connectors ; it is reccomended to check the connector ( Open Up )

and verify a circular mark on the inner rubber seal face to verify the connector fully seated

when assembled. This does not apply to f - style connectors with "O" Rings.

How To Use STUF

How to use STUF Dielecric Waterproofing Filler Grease as a filler in outdoor coaxial connectors for protection from moisture and weather corrosion electrolytic failure.